As part of my Senior Capstone project at Santa Clara University, I have been designing and performing experiments to test the performance of different components. Unfortunately, COVID-19 restrictions prevent me from accessing the university laboratories with power equipment, data acquisition systems, controlled environments, and more. Not letting these barriers stop me, I have been creative, obtaining reasonably inexpensive parts and designing tests I can perform in my garage.

The goal of the project is to build a portable refrigeration system that connects to a bicycle and is powered through generating energy from the pedals. It is intended to help transport medical supplies, such as vaccines and insulin in developing regions around the world where motor vehicles cannot easily access.

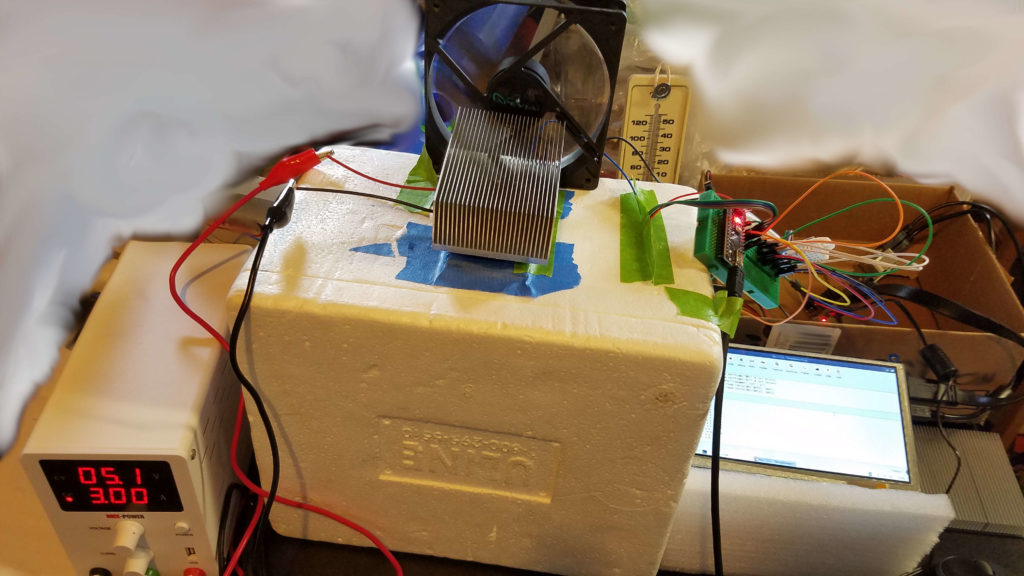

The original tests used a prototype made of a foam box commonly used to ship cold items, an Arduino to provide 5V to a fan, a DC power supply to power the thermoelectric device. Measurements were taken using a meat thermometer from the kitchen to measure the temperature inside the foam box. Unfortunately, we are testing a range between 10-80°F, whereas the thermometer is designed for cooking temperatures, and therefore the resolution and accuracy are poor. It also required manual readings, which are not practical for a device that is intended to be tracked over several hours of testing.

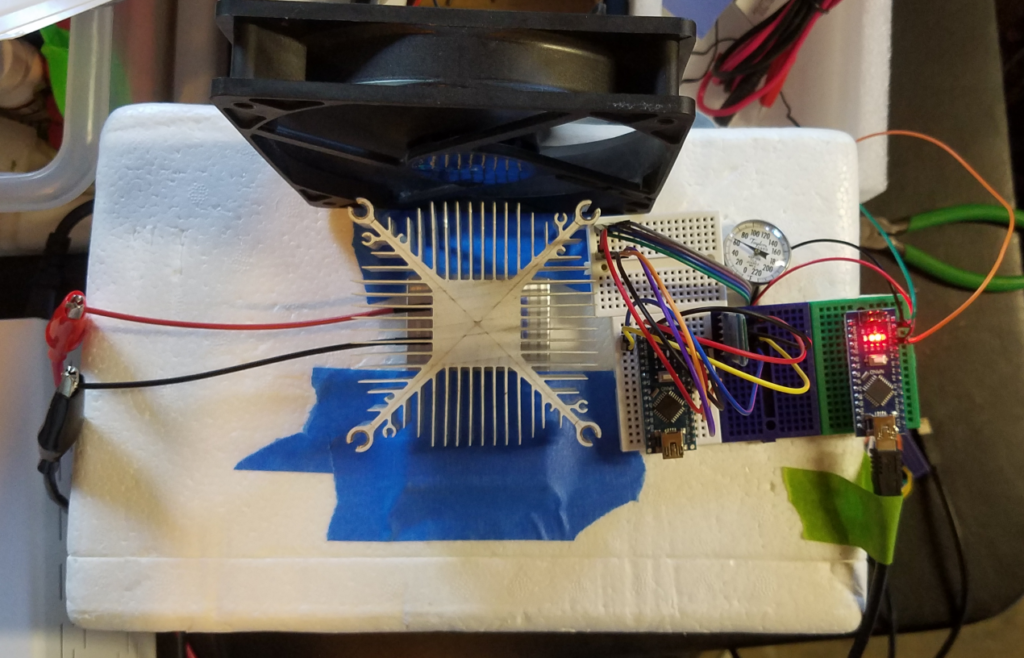

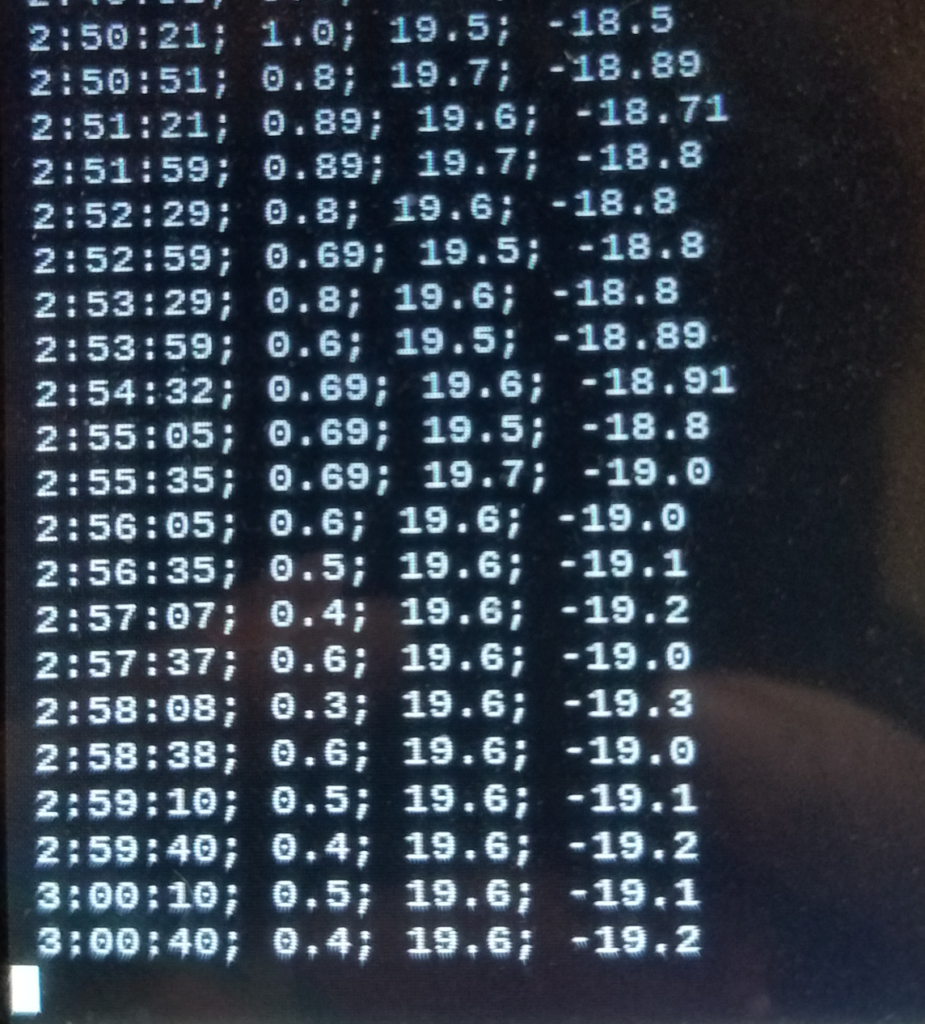

The first full prototype used a Raspberry Pi connected to digital temperature sensors to track the temperature. This provided much better accuracy, and automatically collected data as needed.

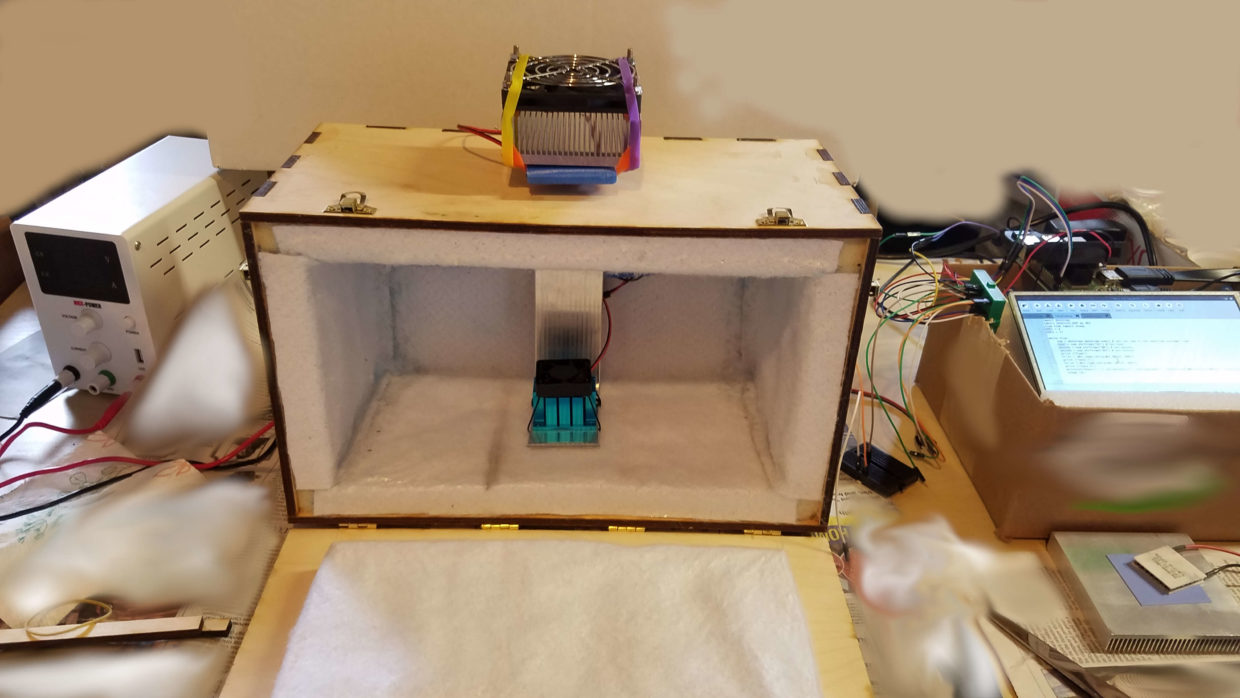

Over the past several months, I have collaborated with my team to design a refrigeration box that is compatible with the mini refrigeration system I have built and tested. This is the testing setup of our final prototype, with the box